As LED display technology continues to develop, COB (Chip on Board) and GOB (Glue on Board), as two advanced packaging technologies, are gradually becoming the focus of industry attention. They not only improve the stability and reliability of the display, but also show obvious advantages in terms of protection performance, display effect and service life. For users who pursue high-quality images and long-term use value, it is particularly important to understand the characteristics and differences between COB and GOB.

This article will explore in depth the principles, advantages and application scenarios of these two technologies to help you have a more comprehensive understanding of the future development trends of LED display packaging technology.

Table of Contents

1.What is COB packaging technology in LED display?

2.Analysis of GOB Packaging Technology in LED Displays

3.The main differences between COB and GOB in LED display

4.Advantages and applications of COB packaging technology in LED display screens

5.Advantages and application scenarios of GOB packaging technology in LED display screens

6.LED display protection capability comparison: COB vs GOB

7.Analysis of LED display effects: Which is better, COB or GOB?

8.How to choose COB or GOB package for your LED display project?

9.In conclusion

1.What is COB packaging technology in LED display?

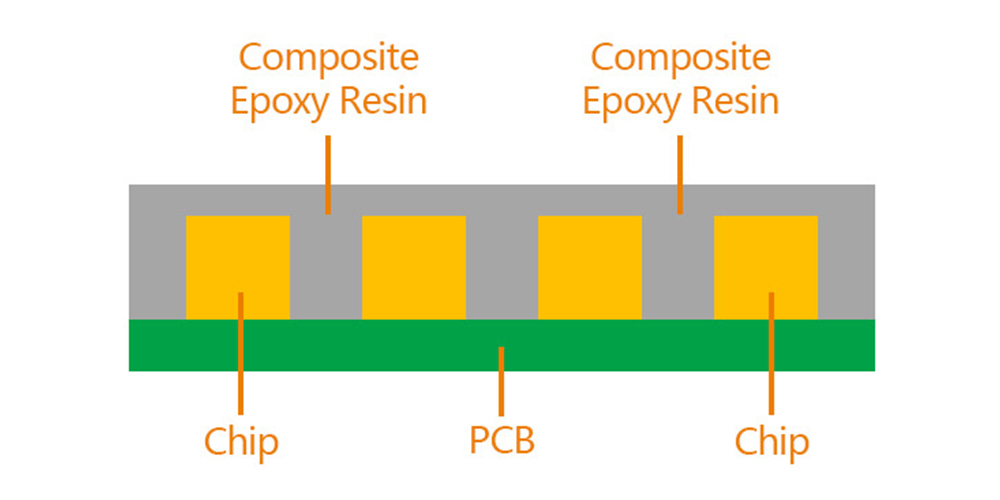

COB (Chip on Board) packaging technology is to directly mount multiple LED chips on the PCB board and uniformly cover them with a layer of packaging colloid, eliminating the traditional bracket and wire bonding structure. This design greatly simplifies the process and improves integration.

Since the light source is closer to the substrate, COB packaging has better heat dissipation performance and higher light efficiency. At the same time, its picture display is more delicate and has higher contrast, which is particularly suitable for small-pitch LED displays to meet high-definition display requirements.

The chip of COB package is covered by packaging materials, which has excellent dustproof, moisture-proof and impact-proof capabilities. Its structure is stable and has strong damage resistance. It is suitable for complex or high-frequency use environments, with lower maintenance costs and longer service life.

Our EA600COB2 series COB LED display is an outstanding representative of COB technology applications and is favored by high-end customers. This series fully utilizes the advantages of COB packaging and performs well in brightness, color accuracy and durability, making it an ideal choice for application scenarios with extremely high requirements for visual quality and product reliability.

2.Analysis of GOB Packaging Technology in LED Displays

GOB (Glue on Board) packaging technology covers the surface of traditional SMD modules with a layer of highly transparent special glue to seal the LED lamp beads as a whole, forming a solid protective layer, thereby improving the overall protection capability of the module.

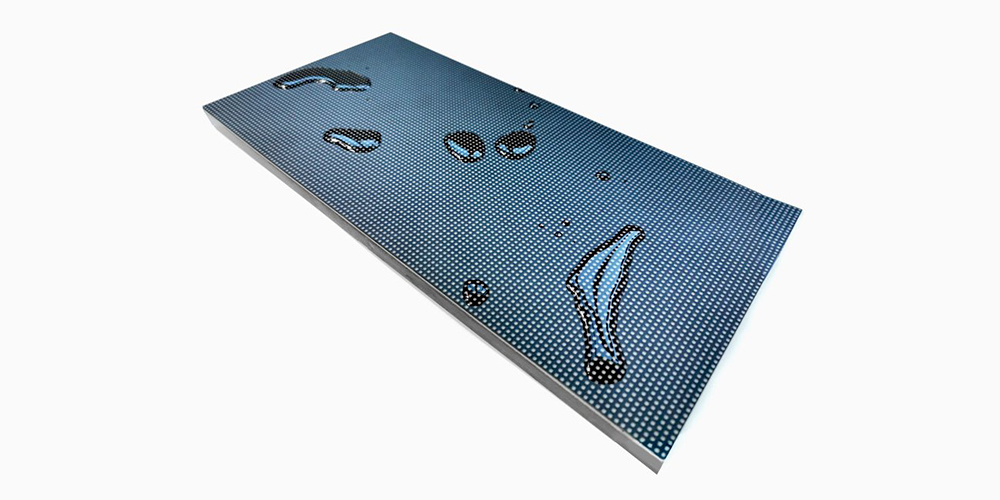

GOB package has excellent waterproof, dustproof, moisture-proof and impact-resistant properties, and is particularly suitable for outdoor rental, outdoor small-pitch and frequent transportation environments, effectively reducing the damage rate of lamp beads and improving safety of use.

While maintaining high-definition brightness and image quality, GOB technology can also effectively reduce the dead light rate, extend service life, and reduce maintenance costs. It is an ideal packaging solution for harsh environments and high-intensity use.

3.The main differences between COB and GOB in LED display

1. Packaging and assembly

COB: COB (Chip on Board) technology is to install multiple LED chips directly on the PCB board, and form an integrated module through overall sealing, omitting traditional brackets and welding wires, and having a higher degree of integration.

GOB: GOB (Glue on Board) is based on the traditional SMD module. The entire module is encapsulated with transparent glue. The structure still retains SMD lamp beads. The assembly method is closer to the traditional LED display and has strong adaptability.

2. Durability and protection

COB: The LED chip in COB package is completely covered and has strong impact resistance, dust resistance and moisture resistance, making it suitable for high-frequency use and harsh environments.

GOB: Although GOB can also provide good protection, its protective layer is surface covering glue. The overall protection strength is slightly lower than COB, but it is still much better than ordinary SMD products.

3. Heat dissipation

COB: In the COB structure, the LED chip is directly attached to the PCB board, with a short heat conduction path and higher heat dissipation efficiency, which can effectively extend the service life of the LED.

GOB: Because GOB has an extra layer of sealing glue, the heat needs to be conducted through the glue additionally. In comparison, the heat dissipation effect is slightly weaker, but it can still meet most common application needs.

4. Optical performance

COB: COB packaging has a smaller pixel pitch and a more uniform light-emitting surface, showing higher contrast and consistency, which is particularly suitable for high-resolution small-pitch LED displays.

GOB: GOB may have slight light reflection or refraction in the adhesive layer that affects brightness, but it still maintains a good display effect overall and is suitable for viewing at medium and close distances.

5. Manufacturing complexity and cost

COB: The COB packaging process is complex and requires high-precision chip mounting and one-time packaging molding. The manufacturing threshold is high, resulting in higher overall costs.

GOB: GOB adds a sealing step based on the SMD module. The process is relatively mature, with high manufacturing efficiency, high yield, and more cost advantages, making it suitable for large-scale promotion.

4.Advantages and applications of COB packaging technology in LED display screens

1. Excellent display effect

COB technology packages multiple LED chips directly on the PCB board, bringing higher brightness and more uniform color, suitable for small-pitch high-definition display scenarios.

2. Excellent heat dissipation performance

The chip is in close contact with the PCB board, which effectively improves the thermal conductivity, reduces heat accumulation, and extends the service life of the LED display.

3. Stronger durability

The overall packaging structure has good dust-proof, moisture-proof and collision-proof properties, and is suitable for complex or high-frequency use environments.

4. Save space and weight

No lamp pins or welding wires are required, the structure is more compact, the screen is thinner and lighter, and it is easy to install and maintain.

5. Application of COB LED display

COB technology is widely used in high-demand scenarios such as retail stores, command centers, and high-end conference rooms. The excellent optical performance of COB displays makes them particularly suitable for applications that focus on visual quality.

5.Advantages and application scenarios of GOB packaging technology in LED display screens

1. Excellent protection performance

GOB (Glue on Board) packaging technology effectively prevents water, dust and moisture from invading by covering the surface of the LED module with a layer of special colloid, significantly improving the protection level of the display. Especially suitable for harsh environments that require long-term stable operation.

2. Improve screen durability

The adhesive layer has extremely high hardness and toughness, which can effectively resist physical damage such as impact and scratch, and extend the service life of the LED display. It is especially suitable for occasions with high frequency of use or crowded areas.

3. Wide range of application scenarios

Outdoor applications: such as outdoor billboards, transportation hubs, stadiums and other places, can withstand rain, wind, sand and temperature changes.

Harsh environment: such as factories, construction sites, ports and other areas with high dust and humidity, to ensure stable operation of the equipment.

Rental and stage performances: GOB technology reduces the risk of damage caused by transportation and repeated installation, and is suitable for rental LED screens that are frequently moved.

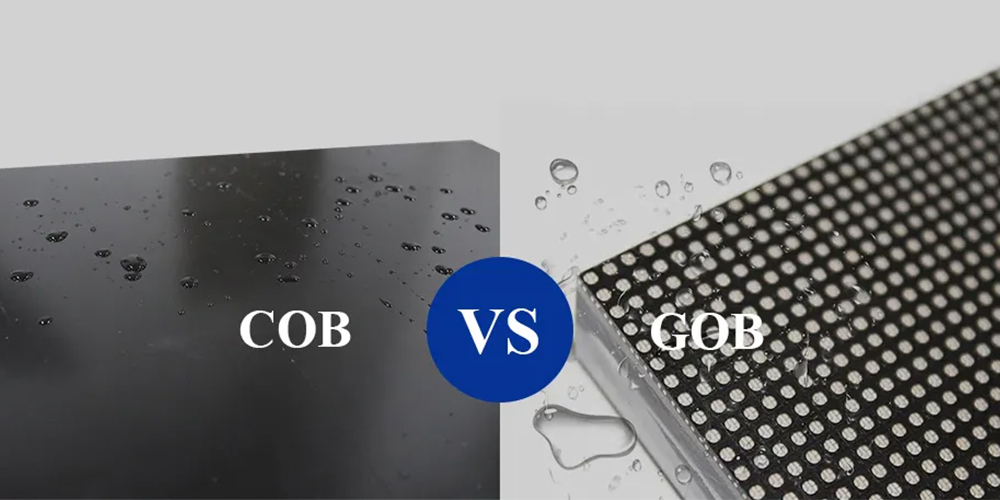

6.LED display protection capability comparison: COB vs GOB

1. Package structure comparison

COB: The LED chip is directly packaged on the PCB board and covered with a layer of epoxy resin to form a highly integrated integrated package with good sealing and stability.

GOB: Based on the traditional SMD lamp beads, transparent polymer colloid is used to cover the entire module surface to protect the lamp beads and circuits and enhance the protection capability.

2. Waterproof and dustproof

COB: Complete packaging, with IP65 or even higher protection level, can effectively resist the intrusion of water vapor and dust, suitable for extreme environments such as high humidity and wind and sand.

GOB: The adhesive layer has good sealing and waterproof and dustproof capabilities, suitable for conventional outdoor environments, but its overall sealing performance in extreme climates is slightly inferior to COB.

3. Impact resistance

COB: Since the chip is directly embedded in the board, the structure is compact, but the ability to resist external impact is limited. Once damaged, it is relatively difficult to repair.

GOB: The adhesive layer has good flexibility and cushioning effect, which can effectively prevent the lamp beads from falling off or being damaged due to impact. It is suitable for frequent operation scenarios such as rental performances.

4. Difficulty of maintenance and repair

COB: The chip and circuit are highly integrated. Once a bad point appears, the entire module needs to be replaced, which makes maintenance complicated and costly.

GOB: The module structure is close to the traditional SMD, which is more convenient to maintain and can be partially repaired. It is suitable for commercial occasions with high requirements for efficiency.

5. Comparison of application scenarios

COB: More suitable for high-end indoor display environments, such as command and control centers, conference rooms, medical systems, etc., where extremely high display accuracy and stability are required.

GOB: Widely used in outdoor billboards, transportation hubs, construction sites, stadiums, stage rentals and other occasions that require high protection and impact resistance.

7.Analysis of LED display effects: Which is better, COB or GOB?

COB: The display effect is exquisite and the brightness is uniform. Due to the use of chip-level packaging technology, the distance between lamp beads is smaller, and higher pixel density is supported. It is especially suitable for small-pitch display applications of P1.2 and below. It has higher resolution and contrast, excellent color reproduction, and is suitable for high-precision display scenarios such as conferences, monitoring, and command centers.

GOB: Good display effect, suitable for mainstream small-pitch products. Although its brightness and contrast are slightly lower than COB, GOB uses traditional lamp beads combined with glue layer protection. It still has strong picture expression in the P1.5-P2.5 range, bright colors, strong visual impact, and is more suitable for applications that do not require extreme details but have high requirements for environmental adaptability, such as outdoor advertising, commercial displays, etc.

COB: It has higher reliability and consistency, almost no lamp bead falling off or color difference problems, the picture is more integrated and the viewing experience is more natural.

GOB: The display consistency is better than ordinary SMD, but slight brightness unevenness may occur at extremely small pitches, especially when splicing large areas, precise correction is required.

Overall, COB performs better in high-definition display, especially in the field of small pitch; GOB achieves a balance between durability and cost-effectiveness, meeting most commercial-grade display needs. The choice should be weighed according to the specific usage scenario.

8.How to choose COB or GOB package for your LED display project?

COB: If your project has extremely high requirements for display accuracy, such as the need to achieve a small pitch screen of P1.2 or below, and pursue high contrast, high brightness and color consistency, COB is a more ideal choice. It is suitable for high-end indoor application scenarios such as conference rooms, command and dispatch centers, and studios, especially for long-term use and close-up viewing.

GOB: If the project is located outdoors or in a complex environment, or the screen needs to be moved, disassembled, or installed frequently, such as stage rental, outdoor advertising, or transportation hubs, GOB is more cost-effective due to its excellent anti-collision, waterproof, and dustproof capabilities. It is particularly suitable for small-pitch displays from P1.5 to P2.5, taking into account both visual effects and durability.

COB: The one-time investment is high, but the maintenance cost is low and the lifespan is long. It is more suitable for customers who want long-term fixed installations and pursue the ultimate in image quality.

GOB: Lower initial cost and easier maintenance, suitable for projects with limited budget but high protection requirements for the use environment.

9.In conclusion

COB and GOB technologies each have their own advantages in the field of LED display screens. COB technology has excellent optical performance and heat dissipation capabilities, which is very suitable for high-end indoor LED display screen applications. GOB technology, with its excellent protection performance and durability, is more suitable for outdoor and complex environment LED display screens.

Whether you pursue the ultimate display effect of COB or prefer the ruggedness and reliability of GOB, EagerLED can provide you with professional and efficient LED display solutions.