LED Display Factory

Advanced LED display factory in Dongguan, China

16years

LED Display

Industry Experience

5000+m²

Production

Workshop

6000+m²

Monthly

production capacity

90+

Used in

countries/areas

EagerLED LED Screen Factory

EagerLED is a leading LED display manufacturer, committed to providing high-quality LED display products to customers around the world. Our modern factory is located in Dongguan, China, with an area of more than 5,000 square meters, equipped with world-leading automated production equipment and efficient production lines.

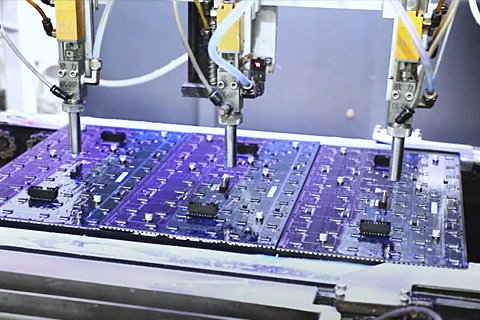

Our production facilities include advanced surface mount technology (SMT) equipment, professional production lines, assembly lines and aging lines, covering every link from raw materials to finished products. Provides a solid guarantee for the production of high-quality LED display walls.

LED Display Factory Production Line

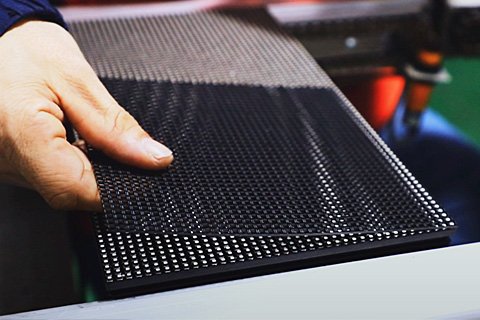

LED Module Production Line

EagerLED LED display factory is equipped with first-class automated production equipment, which is the basis for us to achieve efficient and high-quality production. In particular, the surface mount technology (SMT) equipment we introduced can efficiently and accurately mount LED components on circuit boards to ensure the reliability and consistency of each LED display.

1. LED lamp baking

2. PCB SMT

3. LED SMT

4. Light on test

5. Brush three anti-paint

6. Install the bottom case

7. Glue filling

8. Install the mask

9. QC test

Assembly and Aging Line

We ensure that the assembly of each LED display meets the highest quality standards. EagerLED has an aging line, which simulates the actual use conditions by running it for a long time, and finds and solves potential problems in advance.

1. LED module aging

2. LED cabinet assemble

3. LED screen aging

LED Display Factory OEM Service

EagerLED provides factory OEM services and welcomes consultation and cooperation.

Brand Custom Logo

Special Requirements

Privacy Protection