Quality control

Are you worried about the quality of the LED screen board before paying the balance? As a leading LED display manufacturer, EagerLED has a strict quality control system. We conduct strict quality inspection on every step of LED signage production. We provide a quality inspection checklist for LED video walls. Below you will learn about the complete LED display panel quality control process.

Before LED Screen Board Production

In order to ensure the quality of LED display screens, we need to develop a comprehensive quality control plan before production, including the selection of raw materials, checking product details and customer confirmation, and clarifying specific production requirements with the factory manager to ensure that the LED display wall meets high quality standard.

Quality material starts it all

Before production, we make sure to carefully review and confirm the quality of the raw materials to ensure that the LED display meets the standards of excellent quality.

Confirm LED screen solution

After the order is confirmed, the product solution must be confirmed with the customer multiple times, including logo, accessories, structure, etc.

Confirm production details

This is the most important part. When arranging an order with the production manager, all requirements must be listed in detail to ensure that every link meets the requirements of the customer’s order.

LED Screen Board Production Process

EagerLED adheres to strict production processes and clean production workshop standards. We are committed to providing comprehensive training to our employees to ensure they strictly follow production requirements. Of course, we also pay special attention to quality inspection during the production process to ensure the excellent quality of the final product.

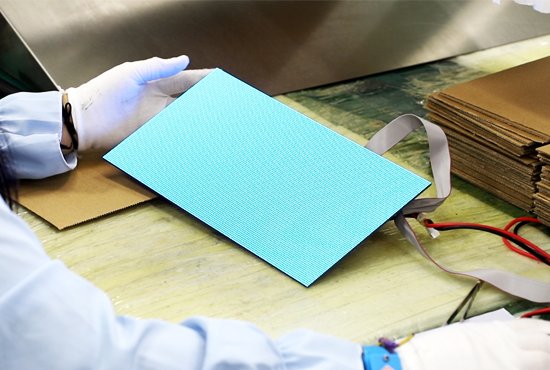

Dust-free production workshop

The dust-free production workshop ensures the brilliant quality of the LED video wall and enhances the stability of the LED screen.

Precision production equipment

Precision production instruments play a vital role in LED display manufacturing, improving production efficiency and product reliability.

Multiplex testing

Through these multiple testing processes, EagerLED comprehensively reviews the quality, stability and reliability of LED displays.

LED module lighting test

EagerLED production team will check each LED wall panel, especially the lighting test.

LED module aging test

LED panel aging test is a very important part before LED cabinet assembly. EagerLED will perform a 24-hour aging test.

Full LED screen aging

After the LED cabinet is assembled, the entire LED screen board is built and subjected to an aging test for at least 72 hours.

After finishing the production

Before the LED screen display is packaged, EagerLED will ensure that there are no dead pixels, consistent colors, and compliance with international quality standards for LED displays. In order to meet your diverse needs, we provide you with two carefully designed packaging methods: flight boxes and wooden boxes. Whether you choose efficient air freight or affordable sea freight, ensure the safety of your cargo.

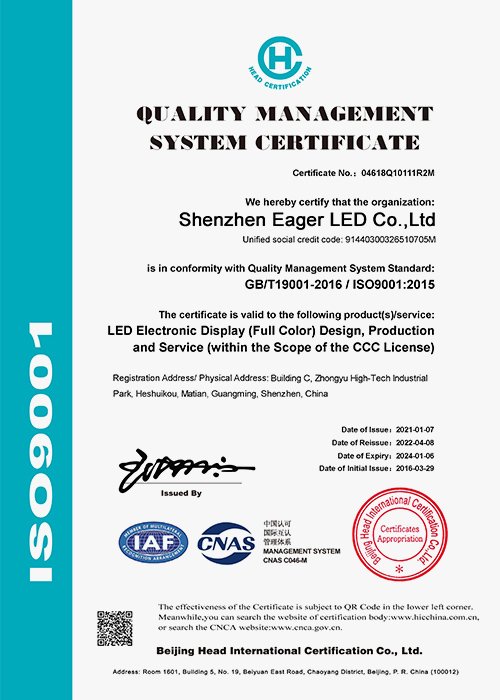

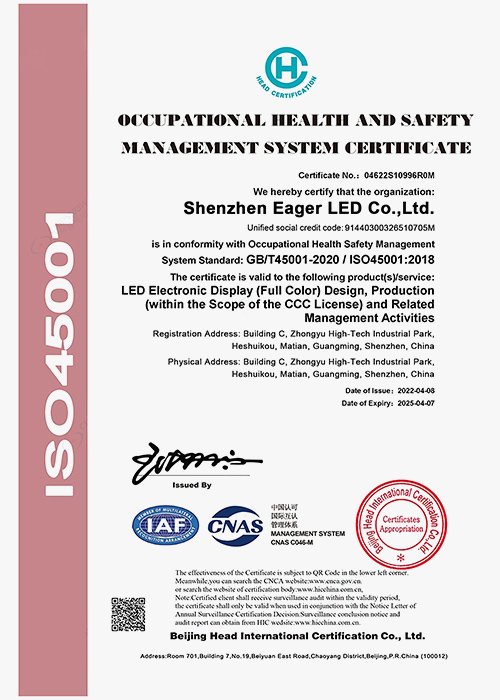

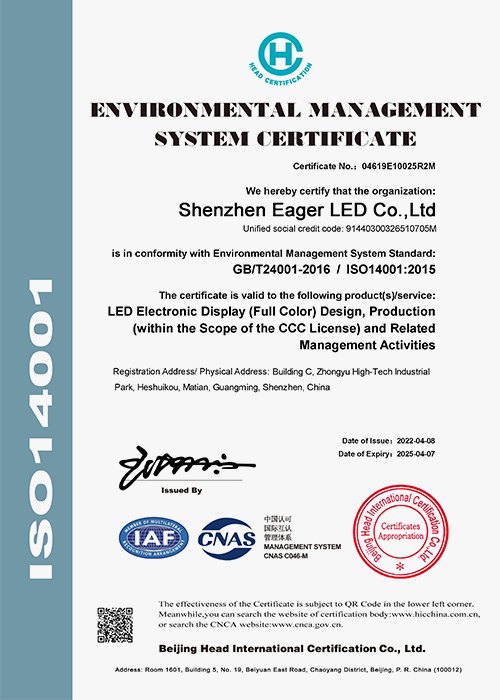

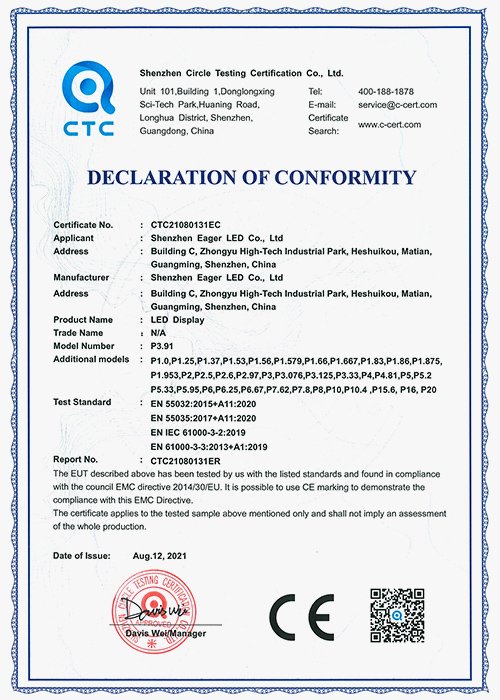

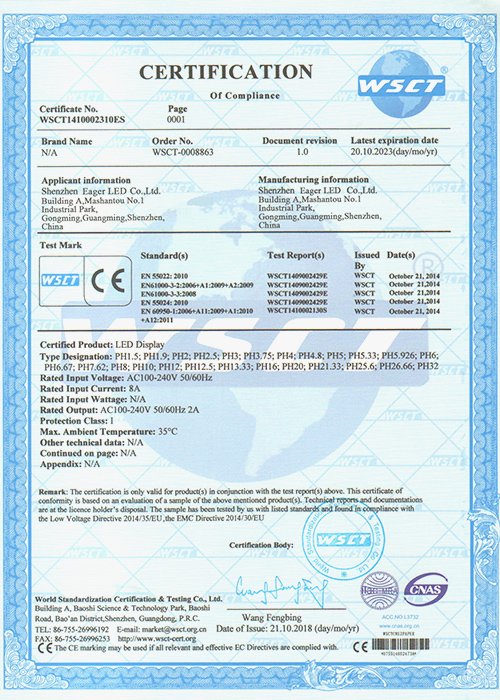

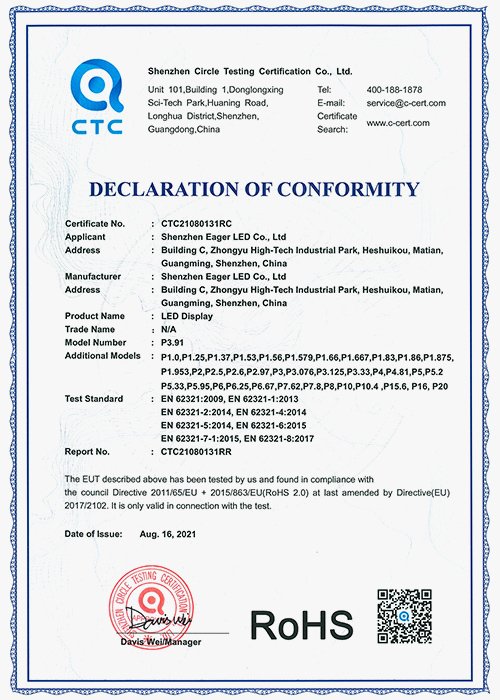

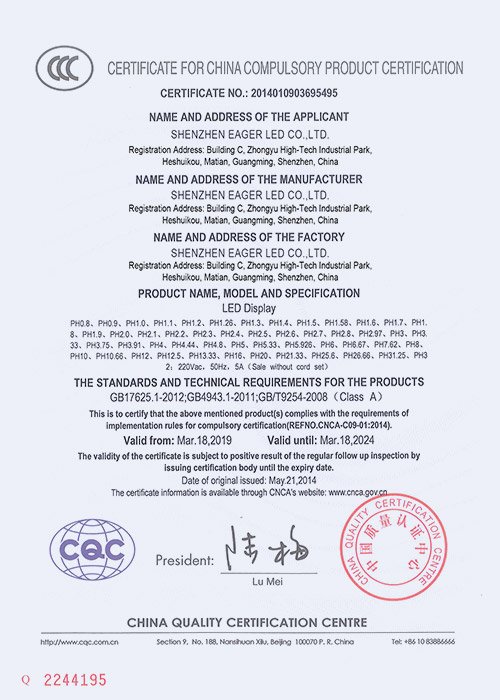

LED Screen Board Certification

EagerLED is a leading LED screen manufacturer, specializing in LED screen manufacturing for more than 15 years, with strict control management and perfect after-sales service. EagerLED’s products have met global quality standards such as CE, RoHS, and FCC, bringing you a high-quality and reliable visual experience.

ISO9001

ISO45001

ISO14001

CE-EMC

CE-LVD

RoHS

FCC

CCC

GET A QUOTE

—