This article is your express ticket to demystifying the IP rating for LED displays. In just 2 minutes, we will unlock the secrets of this critical metric, exploring how each digit in the rating corresponds to specific levels of protection.

You’ll discover how the IP rating influences the performance of LED displays across diverse environments, be it the harsh outdoor elements or the more controlled indoor spaces. By the end of this read, you’ll be equipped with the knowledge to make informed decisions, ensuring that your LED display investment stands the test of time and environmental challenges.

1.What is an IP Rating?

2.How Does the Company Test IP Rating of LED Displays?

3.Special Waterproof Cabinet Material and Sealing Structure Design

4.The Best IP Rating for LED Displays in Specific Applications

5.Maintenance and Verification of Waterproof Performance

6.IP67 vs IP44 vs IP55 Comparison

7.Is the IP68/IP65 Rating Compatible with Low Waterproof Ratings?

8.How to Choose the Right Waterproof LED Screen?

9.FAQs

10.Conclusion

1. What is An IP Rating?

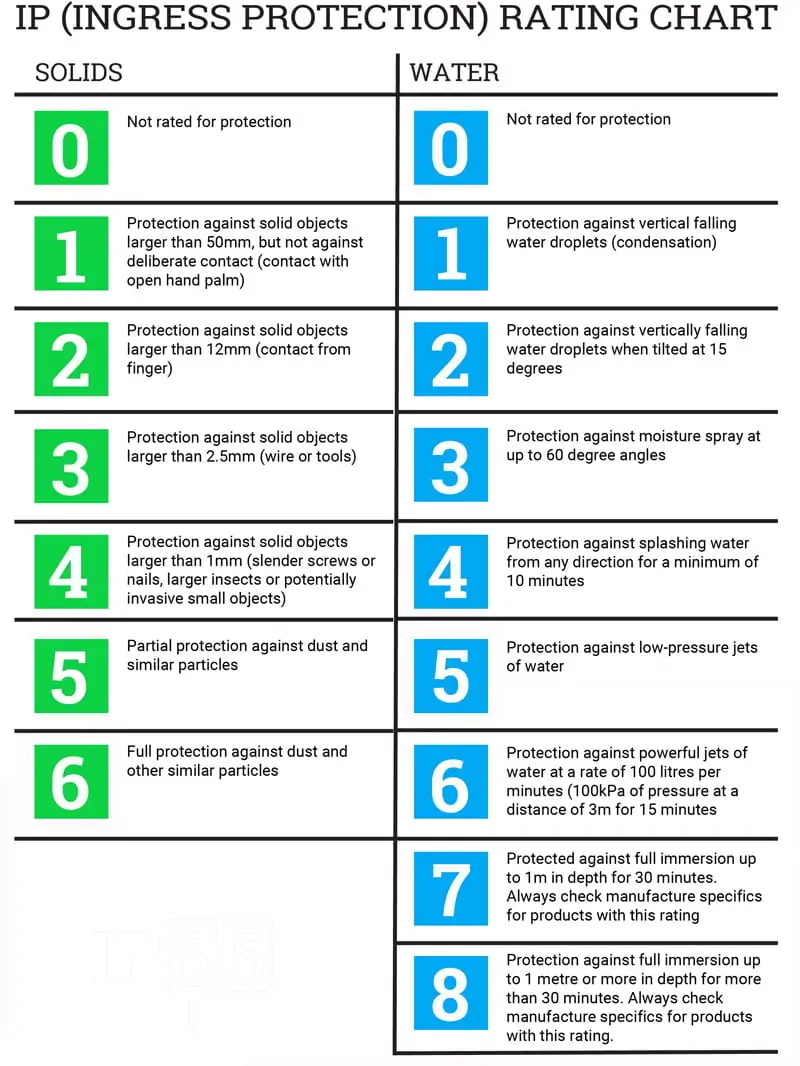

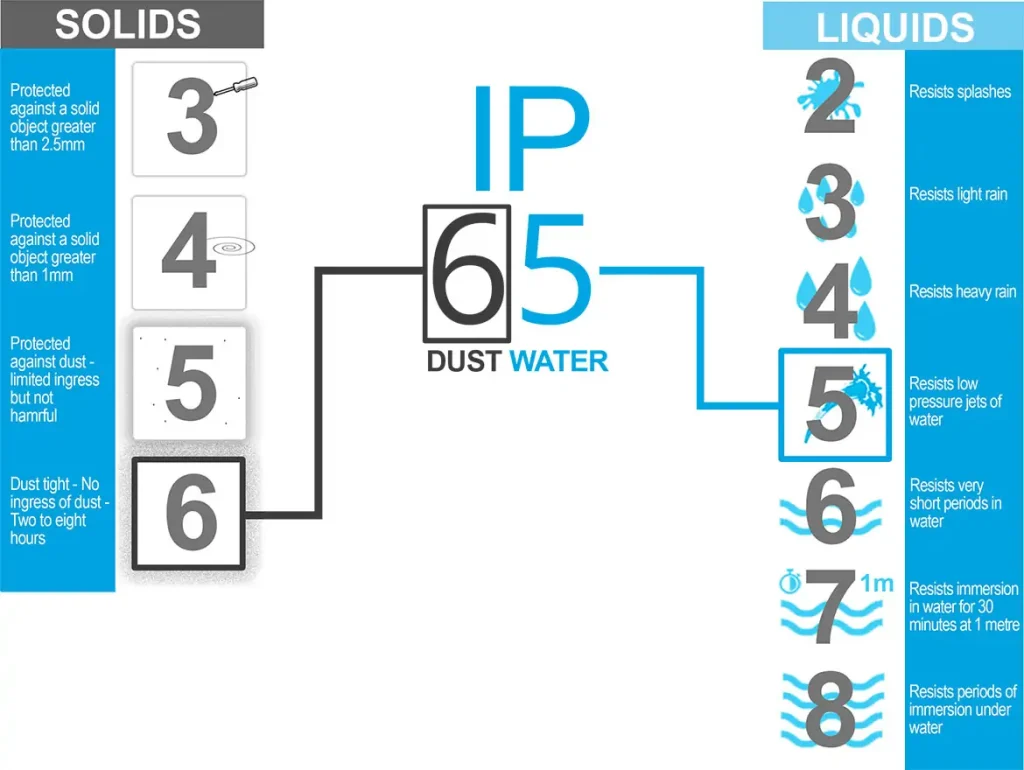

IP Rating (Ingress Protection Rating) is an international standard (defined by IEC 60529) used to classify the level of protection provided by an enclosure or device against the intrusion of solid objects (like dust) and liquids (like water). For LED displays, the IP rating is a critical indicator of their durability and suitability for different environments.

1.1 Structure of an IP Rating

An IP rating typically consists of two digits:

First Digit (Solid Protection): Ranges from 0 to 6, indicating protection against solid objects like dust.

Second Digit (Liquid Protection): Ranges from 0 to 9, indicating protection against liquids like water.

1.2 Highest IP Rating for LED Screens

The highest IP rating for LED screens is IP69K. This rating represents the maximum level of protection against both solid objects (like dust) and liquids (like water). Here’s a breakdown of what IP69K means and its significance for LED screens:

1.2.1 IP69K Breakdown

First Digit (6): Dust-tight: Complete protection against dust and other solid particles. No dust can enter the enclosure.

Second Digit (9K): The device can withstand close-range, high-pressure water jets (80-100 bar) at high temperatures (up to 80°C) from any direction. This is typically tested with a water nozzle at a distance of 10-15 cm.

1.2.2 Applications of IP69K LED Screens

LED screens with an IP69K rating are designed for the most demanding environments, including:

- Industrial Settings: Areas with high levels of dust, moisture, or frequent cleaning with high-pressure water jets.

- Outdoor Harsh Environments: Locations exposed to extreme weather conditions, such as heavy rain, snow, or sandstorms.

- Food and Beverage Industry: Environments requiring frequent sanitation with high-pressure, high-temperature water.

- Marine and Underwater Use: Applications where the screen may be exposed to continuous immersion or splashing.

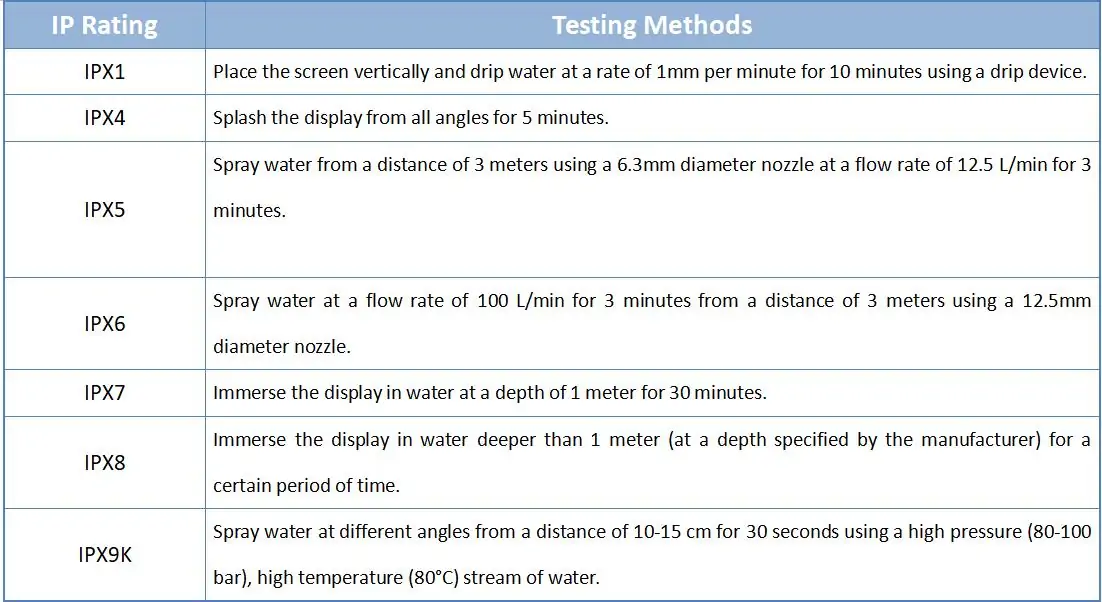

2. How Does the Company Test IP Rating of LED Displays?

LED display manufacturers typically test their waterproofing ratings in accordance with the international standard IEC 60529, which defines the test method for IP Protection Rating (IP rating). The Ingress Protection Rating is the second number in the IP rating (e.g., “5” in IP65) and indicates how well a device protects against liquids. Below are detailed steps and methods for manufacturers to test the waterproof rating of LED screens.

2.1 Test Standards

- IEC 60529:Protection level standard set by the International Electrotechnical Commission.

- GB 4208:Chinese national standard, similar to IEC 60529.

2.2 Test Equipment

- Water jet: For testing of IPX1 to IPX6.

- Water immersion tanks: for IPX7 and IPX8 testing.

- High-pressure, high-temperature water jet: for IPX9K testing.

- Sealing test equipment: for checking the sealing performance of the display.

2.3 Testing Methods

2.4 Testing Process

1.Sample Preparation: Select a sample of the LED display to be tested.

2.Installation and sealing check: Ensure that the display is installed and sealed in accordance with the design requirements.

3.Conduct Test: Select the appropriate test method to conduct the test according to the target IP rating.

4.Evaluate results: After testing, check for water ingress inside the display and evaluate whether its performance has been affected.

5.Record and certify: The test results are recorded and, if the test is passed, the appropriate IP rating is issued.

3. Special Waterproof Cabinet Material and Sealing Structure Design

Waterproof LED display cabinet structure design and sealing material design is to ensure the stable operation of the LED display in outdoor or humid environments. The following are the design points:

3.1 Characteristics of Waterproof Cabinet Material

- Die-casting Aluminum Cabinet: Lightweight (single box ≤ 9kg), seamless splicing, strong pressure resistance (50KN), support IP66/IP68 protection grade.

- Aluminum Alloy Cabinet: Strong thermal conductivity, salt spray corrosion resistance, with sealing tape to achieve IP65 protection.

- Carbon Fiber Cabinet: It is ultra-thin (customizable thickness), high-strength (tensile strength ≥ 1500kg), lightweight (9.4kg/m²), and supports right-angle splicing.

- Magnesium Alloy Cabinet: Corrosion resistance, excellent heat dissipation, suitable for high humidity or salt spray environment, supports IP69K protection.

3.2 Core Seal Structure Design

3.2.1 Sealing Materials

- Silicone sealing strip/liquid silicone: used to fill the seams of the box to prevent water vapor penetration (commonly used in die-cast aluminum and carbon fiber boxes).

- Waterproof Adhesive/UV Glue: Enhance the sealing of joints and seams, combined with the design of glue injection groove to realize double protection.

- Three-proof paint spraying: circuit board surface spraying to prevent moisture erosion.

3.2.2 Structural Design

- Concealed Cable Routing: Integrated internal cable routing to avoid external cable exposure and minimize the risk of water seepage.

- Microporous Breathable Membrane: Covered with heat dissipation holes (0.2μm pore size), allowing air circulation but blocking water vapor.

- Modular Splicing: 45° right-angle edge design reduces the number of seams and improves overall sealing.

3.2.3 Heat Dissipation and Waterproof Compatibility Program

- Liquid Cooling Technology: Insulating coolant is injected into the sealed cabinetto realize efficient heat dissipation under IP68 protection.

- High-Temperature Resistant Metal Shell: Magnesium alloy cabinetwith high-temperature resistant sealant to resist the impact of high pressure and high-temperature water flow.

Therefore, the LED displays usually adopt special waterproof cabinet material and sealing structure design to achieve higher waterproof performance while providing a visually stunning display effect.

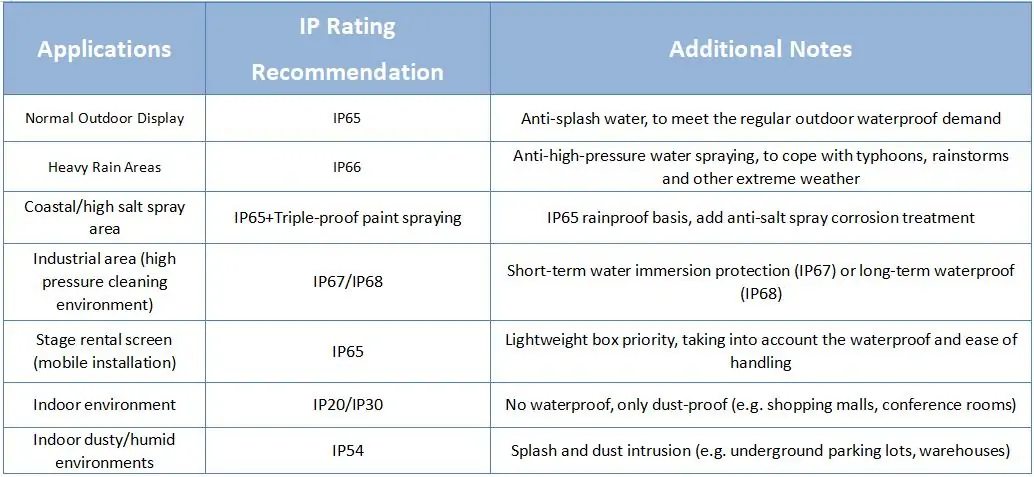

4. The Best IP Rating for LED Displays in Specific Applications

Chart Description:

- IP20IP Rating: For dry indoor environments, no waterproof design required.

- IP44IP Rating: Suitable for wet indoor environments, protected from splashing water.

- IP54IP Rating: Suitable for sheltered outdoor environments, dust and splash-

- IP65/IP66IP Rating: Suitable for outdoor environments without shelter, dust and splash or strong water spray protection.

- IP67/IP68IP Rating: For highly corrosive or underwater environments, dust and splash-

- IP66/IP67IP Rating: For industrial environments, dust-proof and resistant to strong water jets or short-term immersion.

All in all, you need to choose the right IP rating according to your practical use environment. Meanwhile, you also refer to the chart above if you are confused about which IP rating is suitable for your events.

5. Maintenance and Verification of Waterproof Performance

The waterproof performance of LED displays can deteriorate over time due to material aging, structural deformation, and sealing failure. To ensure long-term waterproof performance, regular maintenance and verification are required. The following are key measures for maintaining and verifying waterproof performance:

5.1 Verification Methods for Waterproof Performance

1. IP Rating Test

- IP protection level certification (e.g. IP67/IP68) is required for new screen installation to verify dust-proof and waterproof performance.

- Periodic retesting (once a year is recommended) to simulate water spraying or immersion test to detect whether the sealing is degraded.

2. Water Pressure and Aging Test

- Use the water pressure tester to verify the pressure resistance of the LED cabinetseams (outdoor screen needs to withstand ≥ 1 meter water depth pressure).

- Evaluate the waterproof stability after long-term use through accelerated aging test (continuous operation in high temperature and high humidity environment).

3. Daily Visual Inspection

- Observe whether there are water stains and mold spots on the surface of the LED display, and whether the internal circuit board is oxidized and rusted.

- Detecting whether there are traces of water seepage in key parts such as power supply box and connectors.

5.2 The Impact of Long-Term Use of Waterproof Performance

1. Material Aging Leads to Performance Degradation

- Sealant strips, potting materials in the ultraviolet light or temperature difference may be hardened, or cracked, reducing the sealing properties.

- Box iron shell is susceptible to salt spray corrosion, coastal areas need to be rust-proof treatment every 2 years.

2. Accumulation Of Humidity Triggers Internal Damage

- When not in use for a long time, moisture infiltration may lead to circuit board short circuit or oxidation of lamp beads.

- Condensation accumulation in the heat sink will accelerate the aging of electronic components.

3. Environmental Factors Accelerate Degradation

- Extreme weather such as heavy rain, sand and dust can impact the sealing structure and shorten the protection life.

- Areas with frequent temperature changes, thermal expansion and contraction will easily cause deformation of the box and expansion of the gap.

5.3 Maintenance Methods for Waterproof Performance

1. Sealing Structure Maintenance

- Regularly check the aging of seals such as box seals and module waterproof rings, and replace cracked or deformed parts in a timely manner.

- Clean up the drainage channel to prevent internal water accumulation due to blockage by dust or foreign matter.

2. Surface Protection Treatment

- Use acrylic protective cover or anti-ultraviolet coating for outdoor screensto reduce the direct impact of rain and ultraviolet damage to the sealing material.

- Avoid high-pressure water gun rinsing when cleaning, use wrung out wet towel to wipe the surface, and quickly ventilate and dry.

3. Internal Moisture Management

- When not used for a long time, remove internal moisture by preheating lighting (30%-50% brightness running for 4-12 hours).

- Under a high humidity environment, add a temperature control system or dehumidification equipment to assist heat dissipation.

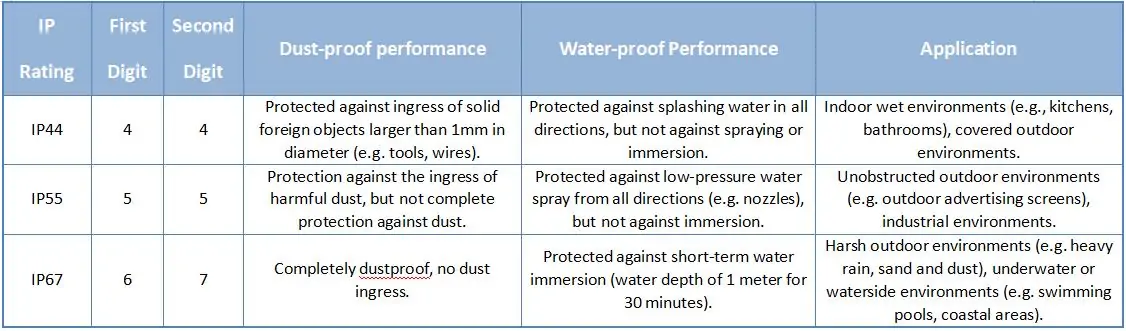

6. IP67 vs IP44 vs IP55 Comparison

Selection Recommendations:

- Indoor environments: IP44is adequate.

- Normal outdoor environment: IP55 is suitable for most outdoor applications.

- Severe outdoor or underwater environments: IP67 provides higher protection and is suitable for extreme environments.

7. Is the IP68/IP65 Rating Compatible with Low Waterproof Ratings?

In the design of LED displays or other electronic devices, the compatibility analysis of IP68/IP65 with lower waterproof ratings (e.g. IP44, IP55) is mainly related to application scenarios, cost, design complexity and maintenance requirements. The following is a detailed analysis:

7.1 Compatibility Analysis

7.1.1 Application Scene Compatibility

- IP65/IP68: Suitable for harsh outdoor or underwater environments with high waterproof requirements.

- IP44/IP55: Suitable for general indoor or mild outdoor environmentswith low waterproof requirements.

Compatibility: IP65/IP68 devices can be used in low waterproof grade environments, but IP44/IP55 devices cannot be used in high waterproof grade environments.

7.1.2 Design Compatibility

- IP44/IP55: Simple design, lower cost, lower sealing requirements.

- IP65/IP68: Complex design, high strength sealing material and structure, high cost.

Compatibility: IP65/IP68 equipment design can be compatible with a low waterproof grade environment, but low waterproof grade equipment can not meet the high waterproof grade requirements.

7.1.3 Cost Compatibility

- IP44/IP55: lower cost, suitable for projects with limited budget.

- IP65/IP68: Higher cost, suitable for projects with high waterproof performance requirements.

Compatibility: IP65/IP68 devices are more costly, but may result in wasted resources in low waterproof rating environments.

7.1.4 Maintenance Compatibility

- IP44/IP55: Simple maintenance and less frequent replacement of sealing materials.

- IP65/IP68: Complicated maintenance, requires regular inspection of high strength sealing material.

Compatibility: IP65/IP68 devices have higher maintenance requirements, but may reduce maintenance frequency in low waterproof rating environments.

7.2 Key Issues of Compatibility

7.2.1 Higher Ratings Replace Lower Ratings

IP68/IP65 devices can replace low waterproof rating devices, but cost and heat dissipation limitations need to be considered (e.g. IP68 fully sealed design may affect heat dissipation efficiency).

7.2.2 Mixed Use Risk

If there are both high and low IP rated components in the system (e.g. IP68 display with IP44 power box), the overall waterproof performance is based on the lowest rated component, which may lead to the risk of water seepage.

7.2.3 Standards Testing Differences

IP68 emphasizes continuous immersion protection, while IP65 is only for water spray protection, the two test conditions are not compatible and cannot be directly equated.

8. How to Choose the Right Waterproof LED Screen?

Choosing the right waterproof LED screen requires careful consideration of several factors, including the environment, technical specifications, and budget. Below is a comprehensive guide to help you make the best decision:

8.1 Determine the Application Environment

The environment where the LED display will be installed is the most critical factor in choosing the right waterproof rating.

8.2 Key Technical Specifications

8.2.1 Pixel Pitch

Indoor Use: Smaller pixel pitch (e.g., P1.2-P3) for close viewing distances.

Outdoor Use: Larger pixel pitch (e.g., P4-P10) for longer viewing distances.

8.2.2 Brightness

Indoor Use: 500-1,500 nits (lower brightness for controlled lighting).

Outdoor Use: 5,000-10,000 nits (high brightness for sunlight visibility).

8.2.3 Resolution

Choose a resolution that matches the viewing distance and content requirements.

8.2.4 Viewing Angle

Wider viewing angles (140°-160°) are ideal for large audiences.

8.2.5 Refresh Rate

Higher refresh rates (≥1,920Hz) reduce flickering and ensure smooth video playback.

8.3 Waterproof Design Features

Sealing Materials: Use high-quality silicone or EPDM rubber gaskets for effective sealing.

Drainage System: Built-in drainage holes to prevent water accumulation inside the cabinet.

Corrosion Resistance: Aluminum or stainless steel cabinets with anti-corrosion coatings for harsh environments.

Modular Design: Easy-to-replace modules and components for maintenance and repair.

8.4 Durability and Maintenance

- Durability: Choose screens with robust materials and high IP ratings for long-term use.

- Maintenance: Opt for screens with easy access to internal components for cleaning and repairs.

8.5 Budget Considerations

- Initial Cost: Higher IP-rated screens (e.g., IP65/IP68) are more expensive but offer better protection.

- Long-Term Cost: Investing in a high-quality waterproof screen reduces maintenance and replacement costs.

8.6 Supplier and Warranty

- Choose a reputable supplier with a proven track record in waterproof LED screens.

- Ensure the product comes with a warranty covering waterproof performance and durability.

8.7 Installation and Support

- Professional installation is crucial for ensuring waterproof integrity.

- Verify that the supplier offers technical support and after-sales service.

In short, choosing the right waterproof LED display involves evaluating the environment, technical specifications, design features, and budget.

9. FAQs

1. How long does a waterproof LED display last?

If you maintain this waterproof LED scree properly, it can last for 5-10 years or more.

2. How waterproof does an outdoor LED display need to be?

Regular outdoor environment needs IP65 or above (anti-spray, dustproof); IP67/IP68 (anti-submergence) is recommended for heavy rain or coastal areas.

3. Can IP55 be used in semi-outdoor scenes (e.g. under canopies)?

It can be used for a short period of time, but we need to pay attention to the risk of rainwater slanting spray or condensate infiltration, and IP65 is recommended to be more secure.

4. How to maintain the waterproof performance after long-term use?

Regularly check the deterioration of the sealing tape (quarterly) ;

Coastal/high humidity areas need to be rust-proof (every 2 years)

5. Can lower ratings (e.g. IP44) be retrofitted to improve water resistance?

Limited, need to add waterproof rubber sleeve or inclined installation for drainage, but cannot reach IP65 or above standard.

6. What is the difference between “splash-proof” and “spray-proof” in the IP rating?

IPX4 (anti-splash water) is suitable for daily rain, IPX5 (anti-spray water) can withstand high-pressure cleaning.

10. Conclusion

By matching the IP rating to your specific environment, you can avoid costly damage, extend the lifespan of your LED display screen, and ensure optimal performance. Always consider factors like pixel pitch, brightness, and maintenance requirements alongside the IP rating to make the best choice for your needs. Contact us to get the perfect solution!